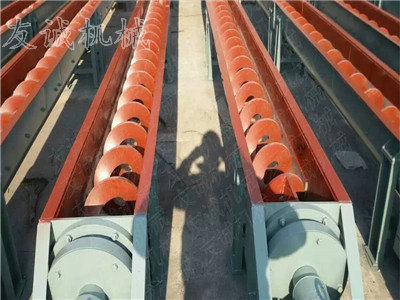

Introduction;it is mainly used for feed sticky materiel(Sludge, mud cake), the materials that Easy to winding(Food waste, kitchen waste), Block materials((Food waste), Shaftless screw conveyor is with reasonable structure, advanced technical indicators, perfect sealed performance, strong applicability, low machine noise, easy operation and maintenance.

it is mainly used for feed sticky materiel(Sludge, mud cake), the materials that Easy to winding(Food waste, kitchen waste), Block materials((Food waste), Shaftless screw conveyor is with reasonable structure, advanced technical indicators, perfect sealed performance, strong applicability, low machine noise, easy operation and maintenance. Its type is expressed by WLS, shaftless screw conveyor is used widely in many fields .

characteristics and range of application

Shaftless screw conveyor is mainly used in chemical, food, medicine, paper making, beverage, environmental protection industry, such as thick paste (Raw materials, waste paper pulp, malt, sludge), paste viscous material (such as chemical raw materials, waste paper pulp, wheat germ, sludge, etc.) and materials easy to wind, it has a unique advantage for these materials.

Advantages: The traditional shaft screw conveyor and belt conveyor are not suitable for granular and powdered materials. wet and paste material.,semi-fluid and viscous material and material that easy to windand plug.But shaftless screw conveyor are suitable for these materials. compare to other Traditional shaft screw conveyors, it uses Flexible overall steel spiral to move the materials, so it can resist tangling, it can convey materials that easy to wind

operating requirements

a、

shaftless screw conveyor should be no-load starting,it means that it is started when there is no materials in the machine,it can convey materials after start.

b、

The operater Should gradually increase the materials until reach the rated throughput

If not, it is easy to cause material jam, it will damage the machne.

c、

In order to make sure no-load starting,the machine should stop feeding materials before power-off,

d、

Hard large materials should not go into the machine,it will cause the spiral stuck, it is bad for machine.

e、

Aways check the working condition of machine,to check if All fasteners are loose.

f、

Do not take away the cover of WLS ,to avoid safety accident